Introduction to Control Cables

Control Cables are integral components in numerous electrical systems, serving as conduits for signal transmission and power distribution. Defined broadly, control cables consist of one or more insulated conductors designed to transmit control signals from one point to another. Their construction typically features multiple wires, each insulated separately, and often includes an outer protective sheath that safeguards against environmental factors, ensuring durability and longevity. Control Cables

The importance of Control Cables cannot be overstated, as they play a critical role in a wide array of applications across various industries. These cables are primarily utilized in automation systems, machinery, and process control, facilitating seamless communication between control devices and equipment. In industrial settings, control cables are paramount for maintaining operational efficiency, ensuring precise command execution, and enhancing safety measures through reliable transmission of signals.Control Cables

Control Cables find applications in sectors such as manufacturing, telecommunications, transportation, and energy. For instance, in manufacturing plants, these cables are essential for linking programmable logic controllers (PLCs) with machinery, thereby enabling automation and efficient workflow management. In the telecommunications industry, control cables are employed for signal transmission and interconnecting diverse network components. Similarly, they are pivotal in transportation systems, such as railways and airports, where they support signaling and control mechanisms.

Moreover, the role of Control Cables extends to energy management systems, where they facilitate the transmission of data and commands in power networks. The construction of these cables is specifically designed to withstand various environmental conditions, including temperature fluctuations, moisture, and mechanical stress, ensuring optimal performance in diverse applications.

TMT Global Technology Ltd: Company Overview

TMT Global Technology Ltd, established in the early 2000s, has emerged as a significant player in the control cable manufacturing industry. Headquartered in the United Kingdom, the company was founded with a clear vision of delivering high-quality control solutions that cater to a diverse range of industries including telecommunications, automotive, and aerospace. Over the years, TMT Global Technology Ltd has successfully carved a niche for itself by focusing on innovation, service excellence, and customer satisfaction.

The mission statement of TMT Global Technology Ltd is centered around providing reliable and efficient control cables that meet the evolving needs of its clients. With a commitment to quality, the company employs stringent quality control measures and adheres to international standards, ensuring that its products not only meet but exceed customer expectations. The corporate values of TMT Global Technology Ltd emphasize integrity, accountability, and teamwork, fostering a culture of continuous improvement and collaboration among its workforce.

Renowned for its cutting-edge technology and design, TMT Global Technology Ltd has strengthened its reputation in the control cable manufacturing sector. The company’s products have been recognized for their durability and superior performance, making them the preferred choice for many leading organizations. This reputation has been bolstered by various industry accolades and certifications, demonstrating TMT Global Technology Ltd’s commitment to excellence. These recognitions showcase the company’s standing in the market and its relentless pursuit of innovation.

TMT Global Technology Ltd continues to invest in research and development, ensuring that its products remain at the forefront of technology trends. This dedication to advancement not only solidifies its market position but also highlights its role as a trusted partner in control cable solutions, poised for future growth and success.

Types of Control Cables Offered by TMT

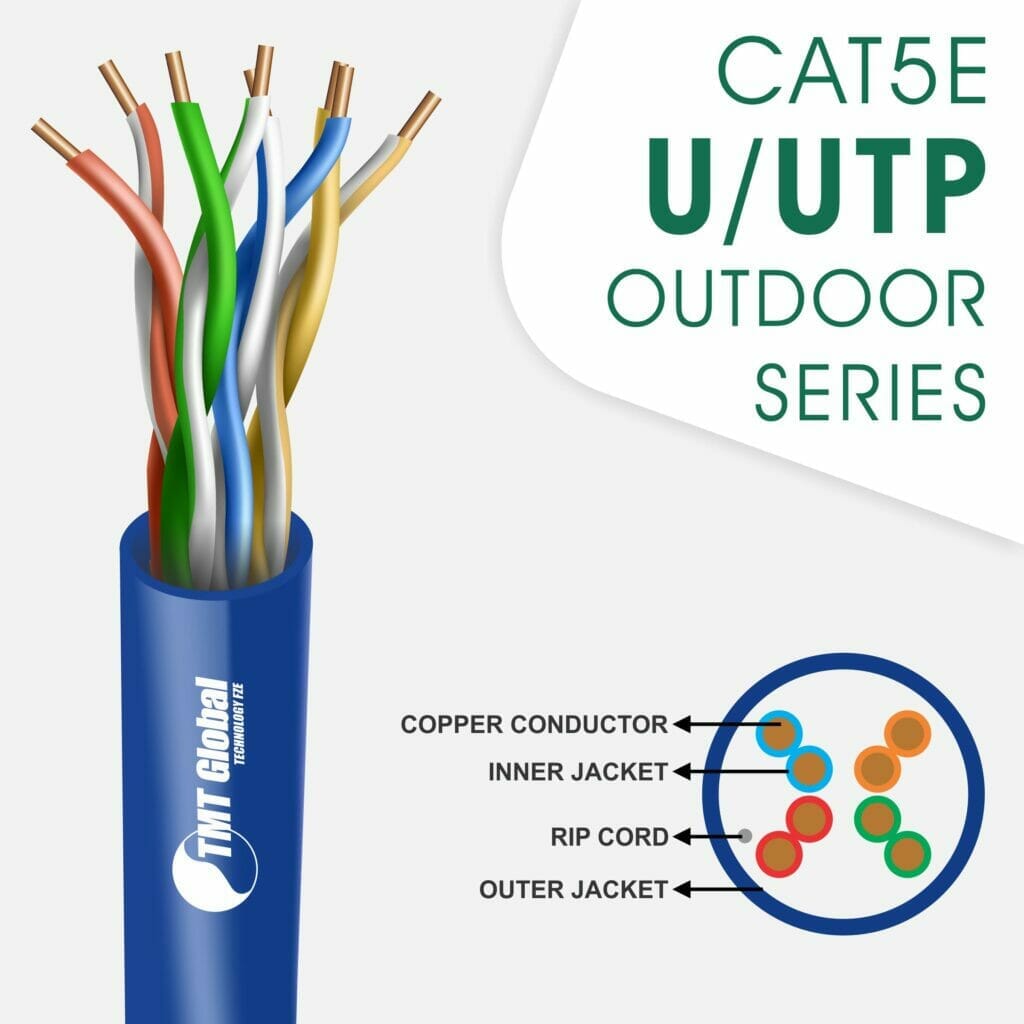

TMT Global Technology Ltd UK offers a diverse range of control cables designed to meet various industry requirements while ensuring safety and reliability. Each type of control cable is crafted with specific materials and construction methods that cater to numerous applications. The first category includes multi-core cables, known for their flexibility and versatility. These cables are typically constructed with several insulated conductors bundled together, allowing for the simultaneous control of multiple systems. The outer sheath is made from durable materials that provide resistance to various environmental factors, making them suitable for both indoor and outdoor use.

Another popular type is the shielded control cable, which incorporates a protective layer around the conductors to prevent electromagnetic interference. This type of cable is particularly advantageous in industries with high levels of electrical noise, such as telecommunications and data transfer applications. The shielding can be made from aluminum or copper foil, enhancing signal integrity and ensuring dependable performance in sensitive equipment.

TMT also specializes in the production of flat control cables, characterized by their unique flat design that allows for space-efficient installation. These cables are typically made from high-quality PVC or thermoplastic elastomer insulation, which enhances their flexibility and ease of handling. Flat control cables are particularly suitable for use in conveyor systems and other machinery where space constraints are a significant consideration.

Finally, TMT offers high-temperature control cables designed for environments exposed to extreme temperatures, such as aerospace, automotive, and processing industries. These cables utilize specialized materials that maintain performance under high heat conditions, ensuring durability and reliability in challenging applications. By providing a comprehensive selection of control cables, TMT Global Technology Ltd ensures that clients have the appropriate solutions tailored to their specific operational needs.

Manufacturing Process of Control Cables at TMT

The manufacturing process of control cables at TMT Global Technology Ltd is a meticulously organized procedure designed to ensure the highest quality, safety, and efficiency. This process begins with the selection of raw materials, where TMT only sources high-grade materials that meet industry standards. The focus on premium materials is crucial, as it forms the backbone of reliable control cable production.

Once the materials are procured, they undergo a series of preparatory steps. This includes insulation, where advanced techniques and materials are used to coat the conductors. The insulation serves multiple purposes, including electrical safety, environmental protection, and enhancing the cable’s flexibility. TMT employs state-of-the-art machinery that guarantees uniform insulation thickness, thereby maintaining product consistency.

The next step involves the assembly of the cables. At TMT, skilled technicians meticulously combine the insulated conductors according to precise engineering specifications. Each cable assembly is further enhanced by incorporating innovative design features that improve operational functionality. TMT prioritizes safety and quality at this stage, adhering to safety standards set forth by international regulatory bodies.

To uphold these standards, rigorous quality assurance protocols are interwoven throughout the manufacturing process. TMT implements a multi-phase inspection system in which each batch of control cables undergoes thorough testing. This includes tensile strength tests, electrical testing, and environmental simulation tests to ensure durability and reliability in various conditions.

Finally, the completed cables are packaged with care, ensuring protection during transportation. TMT’s commitment to technological innovation is evident in its continual investments in production techniques that enhance efficiency and reliability in manufacturing control cables. With a firm focus on quality, safety, and innovation, TMT Global Technology Ltd remains a leading force in the control cable industry.

Quality Standards and Certifications

TMT Global Technology Ltd UK takes pride in its commitment to producing high-quality control cables that meet stringent regulatory requirements and industry standards. The company adheres to a variety of quality standards that ensure the reliability and safety of its products. One of the most notable certifications is the International Organization for Standardization (ISO), which sets a benchmark for quality management systems. Specifically, TMT holds ISO 9001 certification, indicating that their processes in manufacturing control cables are consistently controlled to meet customer expectations and regulatory requirements.

In conjunction with ISO 9001, TMT Global Technology Ltd also complies with ISO 14001 for environmental management systems. This commitment to sustainability shows the company’s awareness of its environmental responsibilities and emphasizes its dedication to minimizing the ecological impact during the production of control cables.

An essential aspect of TMT’s commitment to quality is compliance with the Restriction of Hazardous Substances (RoHS) Directive. This regulation aims to restrict the use of specific hazardous materials within electrical and electronic equipment. By adhering to RoHS, TMT ensures that its control cables are safe for consumers and environment-friendly, catering to industries that prioritize compliance with safety standards.

Moreover, TMT’s control cables are also manufactured in accordance with other international and national standards, such as the Underwriters Laboratories (UL) and British Standards (BS), which further attest to the cables’ reliability and safety. These certifications not only enhance the credibility of TMT Global Technology Ltd but also inspire confidence among clients who seek assurance in the quality and performance of control cables.

Overall, TMT Global Technology Ltd’s adherence to various quality standards and certifications exemplifies its dedication to producing high-quality control cables that fulfill both regulatory demands and customer expectations.

Advantages of Choosing TMT Control Cables

When selecting control cables for various applications, the advantages of choosing TMT Global Technology Ltd are noteworthy. One of the primary benefits is the exceptional durability of their control cables. Designed to withstand harsh environmental conditions, TMT control cables are built with high-quality materials that ensure longevity and reliability. This robustness reduces the need for frequent replacements, ultimately leading to lower maintenance costs over time.

Another significant factor favoring TMT control cables is their flexibility. These cables are engineered to provide excellent bendability, which is crucial in installations where space is at a premium or when cables must navigate tight corners. This flexibility allows for easier handling during installation and enables adaptation to complex layouts, making them ideal for a variety of industrial and commercial applications.

Compliance with regulatory standards is another key advantage of TMT control cables. The company adheres to stringent quality standards and regulations, ensuring that their products are safe and reliable for use in various sectors. This commitment to compliance not only enhances the safety of operations but also instills confidence in customers regarding the quality and performance of the cables they are using.

TMT Global Technology Ltd also places a strong emphasis on customer service and after-sales support. Their dedicated team is available to assist customers with any inquiries or issues related to their control cables. This ongoing support ensures that clients can efficiently utilize the products and address any challenges that may arise after installation. The combination of these advantages makes TMT control cables a wise choice for businesses seeking reliable, high-quality solutions for their electrical needs.

Industry Applications of TMT Control Cables

TMT Global Technology Ltd UK has established itself as a leading manufacturer of control cables, which play a crucial role across various industries. These cables facilitate the transmission of signals and control for equipment used in diverse applications. Control cables from TMT are particularly prominent in the telecommunications sector. They are integral to the functioning of communication networks, ensuring reliable connectivity and the effective transmission of data. Their robustness and adaptability make them ideal for various telecommunications setups, from residential installations to expansive corporate networks.

In the manufacturing sector, the importance of control cables cannot be overstated. TMT’s control cables are utilized for machine automation, allowing for seamless communication between different system components. This includes everything from factory machinery to robotic systems. The reliability of these control cables directly affects productivity, with high-quality cables reducing downtime and maintenance costs, ultimately leading to greater operational efficiency.

The electrical power generation industry also significantly relies on control cables produced by TMT. These cables are employed in power plants, renewable energy installations, and various electrical infrastructures to control and monitor operations effectively. Ensuring that electricity is generated and distributed efficiently requires dependable control cables to facilitate precise signal transmission and system management.

Finally, in the transportation sector, TMT’s control cables are used extensively in vehicles and transport infrastructures. Whether in public transit systems or private automotive applications, control cables assist in ensuring smooth operation, safety mechanisms, and advanced communication within the vehicle. As the transportation industry evolves, the need for high-quality control cables that can withstand dynamic conditions continues to grow.

Overall, the applications of TMT control cables span a multitude of industries, each benefitting from the reliability and technological advancements that these cables represent.

Customer Testimonials and Case Studies

At TMT Global Technology Ltd, we pride ourselves on delivering high-quality control cables that meet the diverse needs of our clients. Our commitment to excellence has been validated by numerous satisfied customers who have shared their positive experiences and successful applications of our products. Feedback from industry professionals not only highlights the reliability of TMT control cables but also emphasizes their efficacy in various demanding scenarios.

One notable testimonial comes from a large manufacturing firm that integrated TMT control cables into their automation systems. According to the operations manager, “Switching to TMT’s control cables has significantly improved our machinery’s performance and minimized downtime. The quality of these cables is unparalleled, and we have experienced zero failures since implementation.” This case demonstrates how our products can enhance operational efficiency and reliability within complex environments.

Another instance involved a renewable energy company that utilized TMT control cables in their wind turbine installations. The project manager stated, “We relied on TMT Global Technology for control cables during the rollout of our wind farms. The cables stood up against harsh weather conditions and proved crucial for ensuring optimal energy output. The durability of their products exceeded our expectations.” This highlights the ability of TMT control cables to perform consistently even in challenging conditions.

Furthermore, in the automotive industry, a client specializing in electric vehicle production reported, “We chose TMT control cables for our EV assembly lines due to their superior heat resistance and flexibility. These cables have played a vital role in our transition toward more sustainable manufacturing practices.” Such testimonials reinforce the versatility and dependability of TMT’s control cables across various sectors.

Through these testimonials and case studies, it becomes apparent that TMT Global Technology Ltd’s control cables not only meet but often exceed industry standards, as evidenced by the success stories shared by our clients.

Conclusion and Future Innovation

In summary, TMT Global Technology Ltd has established itself as a leader in the manufacturing of control cables, offering a diverse range of products that adhere to the highest industry standards. Throughout this blog post, we have examined the company’s commitment to quality, reliability, and the innovative approaches it employs in cable production. TMT’s control cables cater to various applications, providing essential connectivity in sectors such as telecommunications, aerospace, and automation. The emphasis on durability and performance has made these cables integral to modern infrastructure.

Looking ahead, the potential for innovation in cable technology is vast. Continued advancements in materials science may pave the way for lighter, more flexible cables, which will enhance installation ease and adaptability across various environments. Additionally, the integration of smart technology within control cables presents exciting possibilities. TMT Global Technology Ltd might explore the development of cables equipped with sensors that can monitor performance metrics such as temperature, voltage, and signal integrity, thus enabling predictive maintenance and real-time data reporting.

As the demand for high-performance cables continues to rise, particularly within the context of increasingly complex systems and the Internet of Things (IoT), companies like TMT Global Technology Ltd are likely to innovate through enhanced manufacturing processes and sustainable practices. The future may also witness the implementation of eco-friendly materials that not only meet performance demands but also address environmental concerns, a critical consideration in today’s market.

By remaining at the forefront of technological advancements, TMT Global Technology Ltd can continue to set industry standards, ensuring that its control cables remain synonymous with quality and reliability. The journey of innovation is ongoing, and it will be intriguing to observe the paths the company chooses in shaping the future of cable technology.